New Technologies

Select a Story

AquaNereda® Aerobic Granular Sludge Technology

Aqua ElectrOzone™ Ozone Generation System

Aqua MegaDisk™ Cloth Media Filter

ChemScan Mini On-Line Monitoring for Ortho-Phosphorus

AquaNereda® Aerobic Granular Sludge Technology

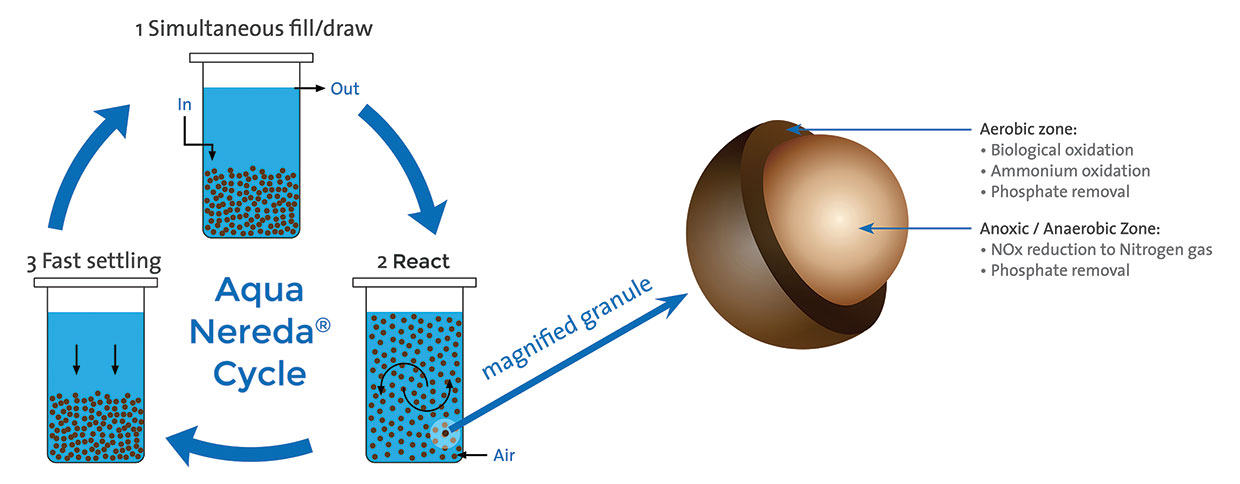

The AquaNereda® Aerobic Granular Sludge Technology is an innovative biological wastewater treatment technology that provides advanced treatment using the unique features of aerobic granular biomass. The unique process features of the AquaNereda technology translate into a flexible and compact process that offers energy efficiency and significantly lower chemical consumption.

Features

- Robust structure of granule withstands fluctuations in chemical spikes, load, salt, pH and toxic shocks

- No secondary clarifiers, selectors, separate compartments, or return sludge pumping stations

- Settling properties at SVI values of 30-50 mL/g allow MLSS concentrations of 8,000 mg/l or greater

- Proven enhanced nutrient removal (ENR)

- Simplified operation with fully automated controls

Advantages

Advantages

- Optimal biological treatment is accomplished in one effective aeration step

- Four times less space required compared to conventional activated sludge systems

- Energy savings up to 50% compared to activated sludge processes

- Robust process without a carrier

- Significant reduction of chemicals for nutrient removal due to the layered structure and biopolymer backbone of the granule

- Lowest life-cycle cost

Applications

- Retrofit of existing tanks, increasing treatment capacity

- Upgrade of existing treatment systems to meet BNR requirements

- New plant construction

- Municipal and industrial

HOW IT WORKS

Batch Cycle Structure

Based on the unique characteristics of granular biomass, the AquaNereda® Aerobic Granular Sludge Technology uses an optimized batch cycle structure. There are three main phases of the cycle to meet advanced wastewater treatment objectives (Fill/Draw, React, Settling). The duration of the phases will be based upon the specific waste characteristics, the flow and the effluent objectives.

Nereda® is a registered trademark of Royal HaskoningDHV.

Aqua ElectrOzone™ Ozone Generation System

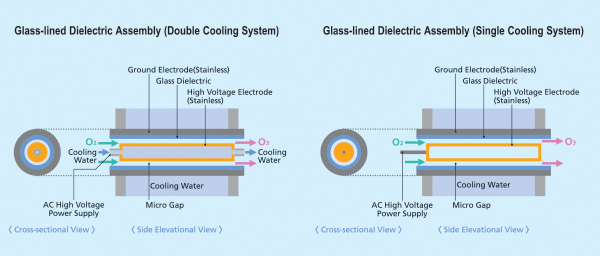

Ozone treatment for water and wastewater has been utilized successfully for several decades and continues to be a viable disinfection solution for both municipal and industrial plants, worldwide.

Aqua-Aerobic Systems is pleased to partner with Metawater, Co., Ltd., a leading ozone provider and developer of MicroGap™ glass-lined dielectric core technology with more than 800 installed systems, worldwide. This partnership allows Aqua-Aerobic to build on the company's expertise and experience in ozone treatment while providing our customers with another quality product solution, the

Aqua ElectrOzone™ Generation System.

Markets Served:

- Potable Water Treatment

- Wastewater/Water Reuse

- Industrial Applications

Features

- MicroGap™ glass-lined dielectric core

- Single and double cooling systems

- Stainless steel elements for high dimensional accuracy

- Solid state pulse width modulation power

- Low harmonics

Advantages

- Highest ozone production per dielectric

- Ten year warranty on dielectrics

- Local parts and service

- Safe operation

- Effective treatment

- High efficiency

- Extremely low failure rates

- Robust design

Applications

- Taste and Odor Control - Oxidation and decomposition of dissolved components into tasteless and odorless soluble substances.

- Bleaching/Color Removal - Coloring components such as pigments and humic substance are decomposed and bleached.

- Oxidation - Effective for decomposition of harmful substances and various types of cleansing.

- Disinfection - Virus, bacteria and fungi are disinfected and made inert.

Aqua MegaDisk™ Cloth Media Filter

Filter Operates in 80% Less Space than Sand Filters!

The new Aqua MegaDisk™ Cloth Media Filter features 30% larger diameter disks and fewer mechanical components in a fraction of the space. The result is more hydraulic capacity and lower capital and O&M cost. For more information visit www.aqua-aerobic.com/index.cfm/products-systems/filtration/aqua-megadisk.

ChemScan Mini On-Line Monitoring Units

WWTP installs new affordable ortho-phosphorus analyzer to help contain escalating chemical costs. - By Dave Marsh

Wisconsin’s Department of Natural Resources recommended a reduction in the state’s phosphorus limit from 1 ppm to 0.05 ppm for inland lakes and streams (0.5 ppm for the Great Lakes) in efforts to improve water quality and reverse eutrophication of state’s lakes and rivers. These new limits when adopted will force many WWTPs to spend more on chemicals and invest in new equipment.

Wisconsin’s Department of Natural Resources recommended a reduction in the state’s phosphorus limit from 1 ppm to 0.05 ppm for inland lakes and streams (0.5 ppm for the Great Lakes) in efforts to improve water quality and reverse eutrophication of state’s lakes and rivers. These new limits when adopted will force many WWTPs to spend more on chemicals and invest in new equipment.

In anticipation of more stringent regulations, operators of Sheboygan’s Waste Water Treatment Plant recently installed the ChemScan Mini oP Online Analyzer manufactured by ChemScan. The Mini oP is a dedicated ortho-Phosphorous analyzer that Sheboygan uses to continuously monitor the ortho-phosphorus levels in the final effluent and through its SCADA system automatically controls the Ferric Chloride (FeCl3) feed rate.

“I’m confident we can meet the lower phosphorus limits,” said Dale Doerr, Sheboygan Regional WWTP Wastewater Superintendent. “But that means our annual Ferric Chloride costs will dramatically increase. In 2009, we spent $160,000 on Ferric Chloride. However, in order to meet the new limits we expect the costs for ferric chloride will increase to $500,000. Obviously this will make it even more critical that we control our processes and use chemicals more judiciously, which was our thinking behind installing the new Mini oP online analyzer.”

Doerr had been researching options for monitoring ortho-Phosphorus but he couldn’t justify the cost until the introduction of the Mini oP. “Our Mini oP was only $12,000, said Doerr. “The next closest solution cost $6,000 more so we were willing to give it a shot. We only have to save 8% on our annual chemical costs to pay for it. From what we have seen it gives us a better phosphorus result, and it should pay for itself in one year.”

Doerr faces the additional challenge of managing a plant that is only staffed 12 hours a day, which meant that during the un-staffed hours the process might not have been receiving optimal levels of ferric chloride.

Doerr faces the additional challenge of managing a plant that is only staffed 12 hours a day, which meant that during the un-staffed hours the process might not have been receiving optimal levels of ferric chloride.

“Before we installed the Mini oP, the operators would draw ortho-Phosphorus grab samples three times a day,” said Doerr. “And based on the results they would either turn on or turn off the Ferric feed to the basins. That worked fine when operators were on duty, but whatever the feed rate setting was when the operator left at 6:00 PM, it would remain at that feed rate setting until 6:00 AM the next morning. Ferric chloride might have been fed all night when it was not needed; and it might not have been fed when it was needed.

Now the Mini oP automatically optimizes our use of Ferric 24/7.” The Sheboygan plant operators are accustomed to fluctuating phosphorous levels and add FeCl3

to complement the plant’s Biological

Phosphorus Removal process. “We take a lot of hauled in waste and most of it is cheese processing waste, high in phosphorus,” said Doerr. “Fluctuations have more to do with how much phosphorus is coming in, than how well the BPR is running.”

Doerr said that tighter government regulations are forcing many plant operators to seek out new methods and technologies for better phosphorus control. “We run this plant like a business and we’re proud to have the second lowest rates of all Wisconsin wastewater treatment plants serving 50,000 and more. But it’s something we’re always working to improve”, said Doerr who began working in wastewater treatment as a plant operator trainee and later went to school to earn a MBA. “If some new system or technology is going to reduce our costs and improve our bottom line, we’re going to take a serious look at it.”

The new ChemScan Mini oP Analyzer is dedicated to analyzing samples of a single parameter, ortho-Phosphorous, from a single sample point, making it an affordable option for controlling the rising costs of meeting tighter phosphorus limits. The Mini oP Analyzer was designed with many of the time tested features of larger ChemScan Analyzers. Its flow paths are designed with larger orifices that avoid plugging, it can operate for three months without replenishing the reagent, and any analyzer component can be replaced in less than five minutes.

“We’ve continued to check the Mini oP against grab samples and it has been consistently accurate. It’s been dead on since we installed it,” said Doerr. “We’ve been on the cutting edge of technology and we’ve tested out many new products and technology. We have a culture that is not afraid of trying new equipment and technologies. If we believe something can benefit our operations we don’t feel we have to wait for someone else to prove it. The Mini oP is working out well for us. We have two process trains and it looks like we’ll be investing in a second Mini oP for our second train.”

For more information visit

www.chemScan.com